Injection device

More InformationsFilter

Functional principle Pumps

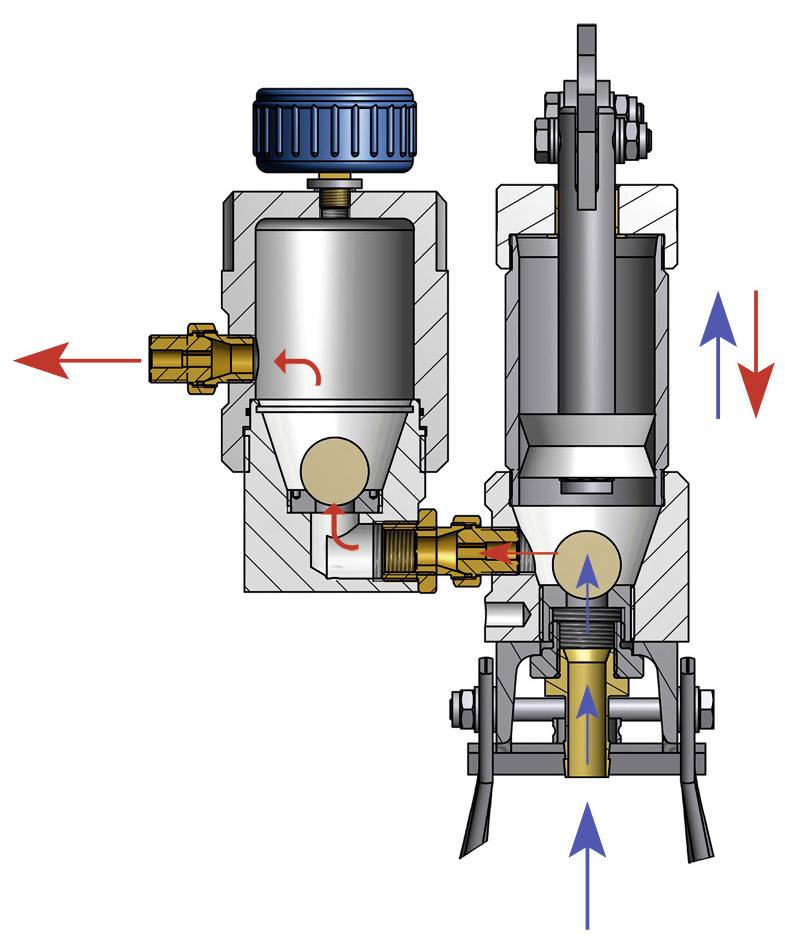

Membrane pump

Membrane pumps are available with mechanical, hydraulic or pneumatic drive. The alternating deflection of the membrane increases and decreases the volume of the pump chamber so that the injection material is drawn in and forced out (direction controlled e. g. by check valves). Advantages: the injection material is separated from the drive, the injection material is handled gently, defined pressures can be achieved.

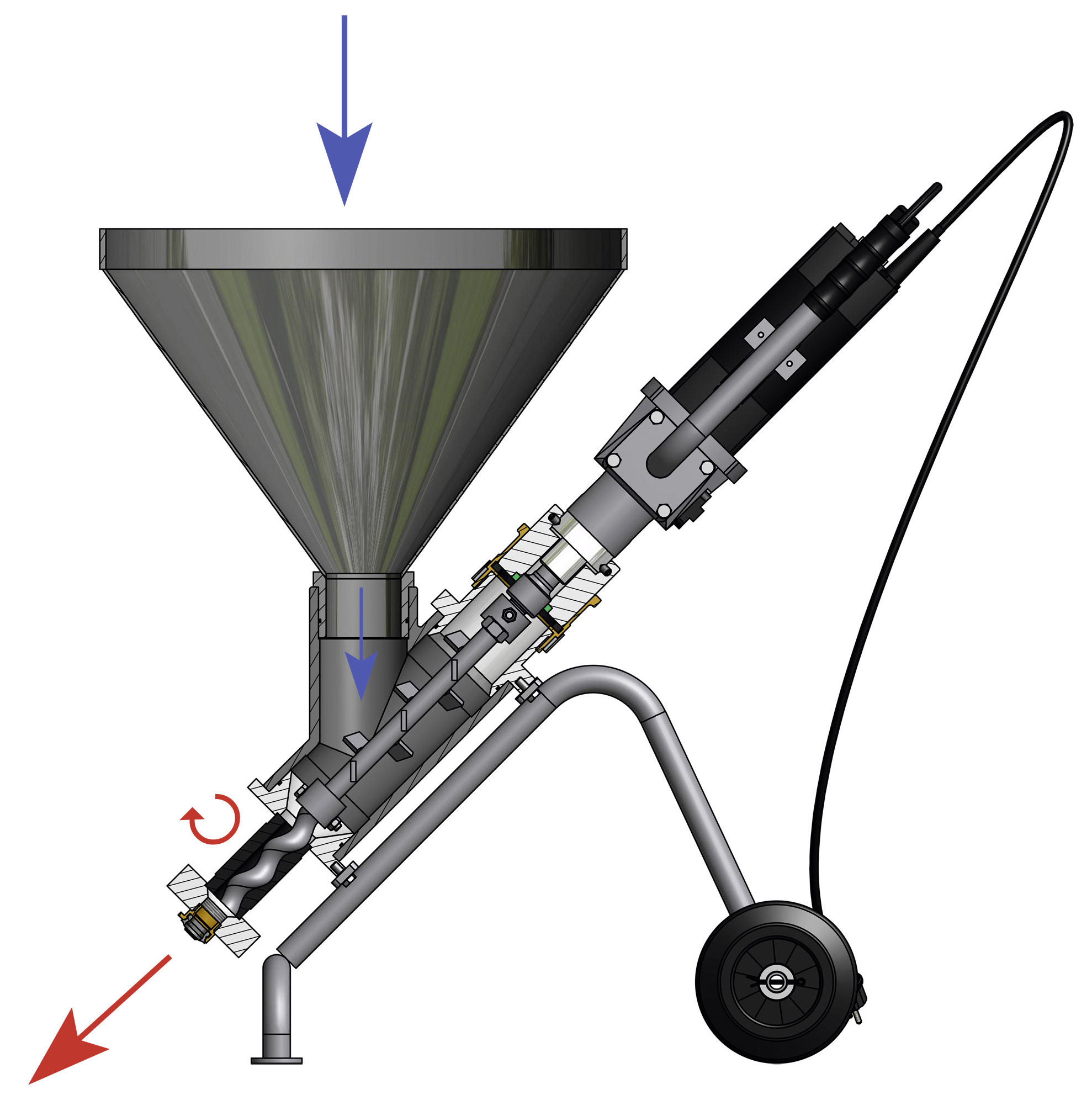

Screw pump

The screw pump works on the principle of archimedes screw. The screw (rotor) is housed in a tight-fitting tube (stator) so that the space between form the pump chamber. By rotating around its own axis the screw delivers the injection material in the pump chamber from the intake side to the outflow. Advantages: easy operation and maintenance, quick cleaning, light weight

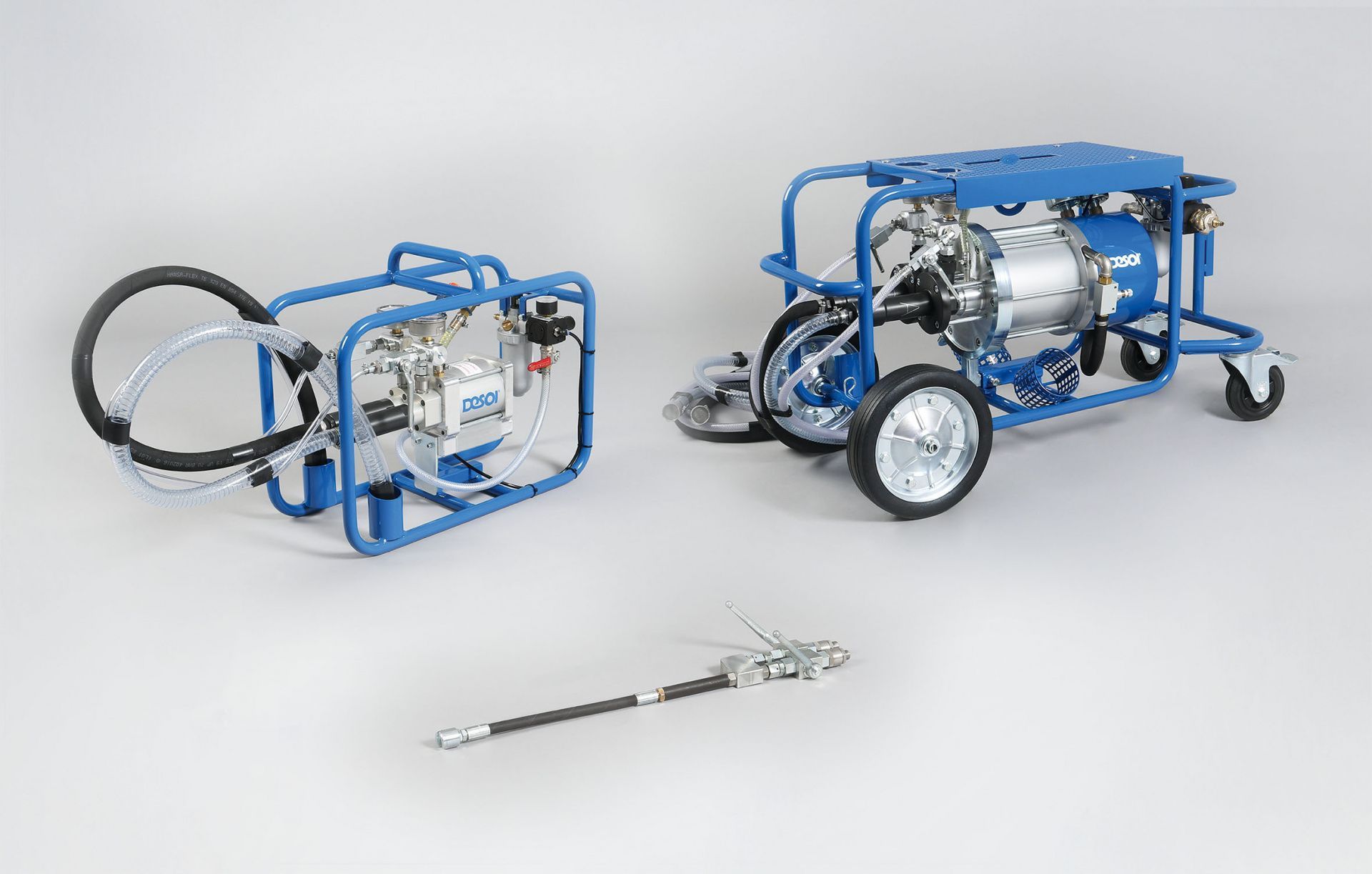

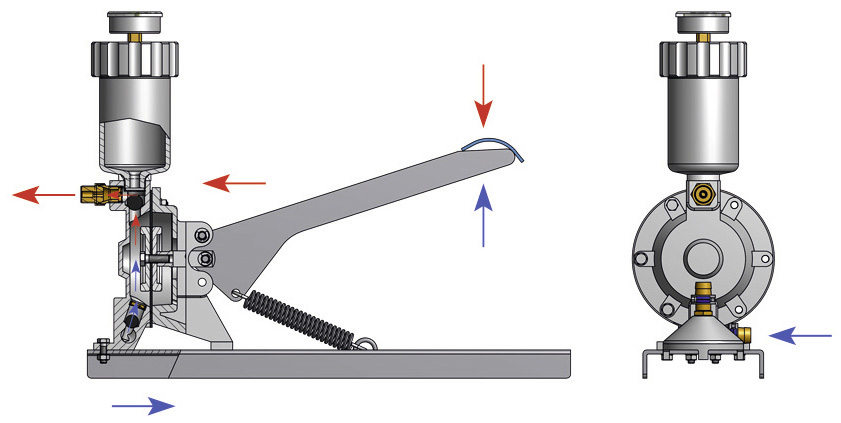

Reciprocating pump

Reciprocating pumps are offered as hand lever, foot lever, electrically or pneumatically operated injection devices. It is possible to achieve high pressures which can be exactly adjusted and monitored by means of pressure gauges. Advantages: space-saving transport, big material passages, accumulator with manometer for pressure control.

Machine comparison 2C and 3C piston pumps

Each injection pump has its own characteristics. Compare the technical specifications at a glance. Which injection pump has the greatest output and what pressures does it operate at?

Try our machine comparison to find out which pump is most suitable for your application.

open PDF

Try our machine comparison to find out which pump is most suitable for your application.

open PDF